MES IOTAR - Production management, control and planning software

Simple and inexpensive interconnectionIOTAR MES supports, controls and manages production

Manufacturing Execution System (MES) refers to a computerized system that has the main function of managing and controlling the production of a company. It allows you to manage orders, generate detailed estimates and final balances, monitor times and costs of each production phase on a single piece, machine and operator data, production planning, quality, traceability and ordinary and predictive maintenance.

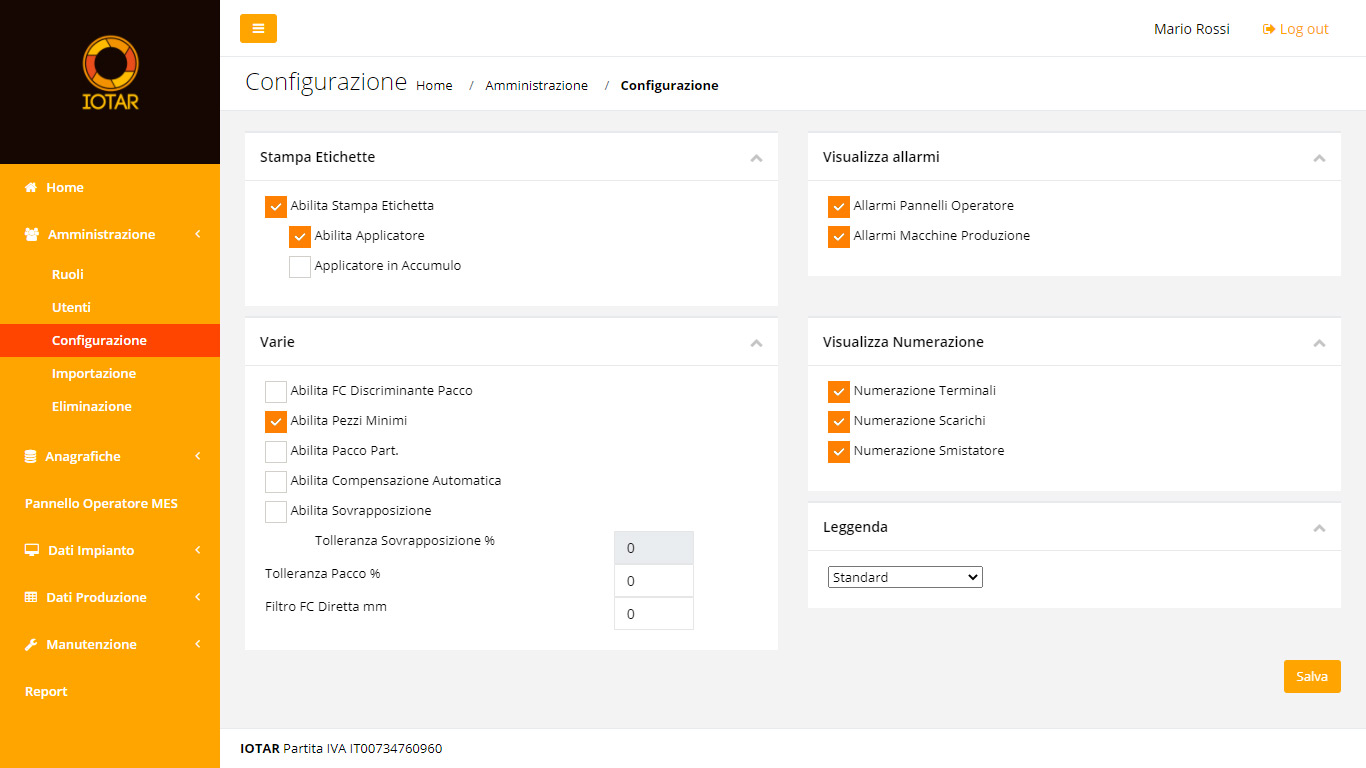

IOTAR MES is a software application that offers the user numerous tools that allow you to easily manage the main data analysis and management activities.

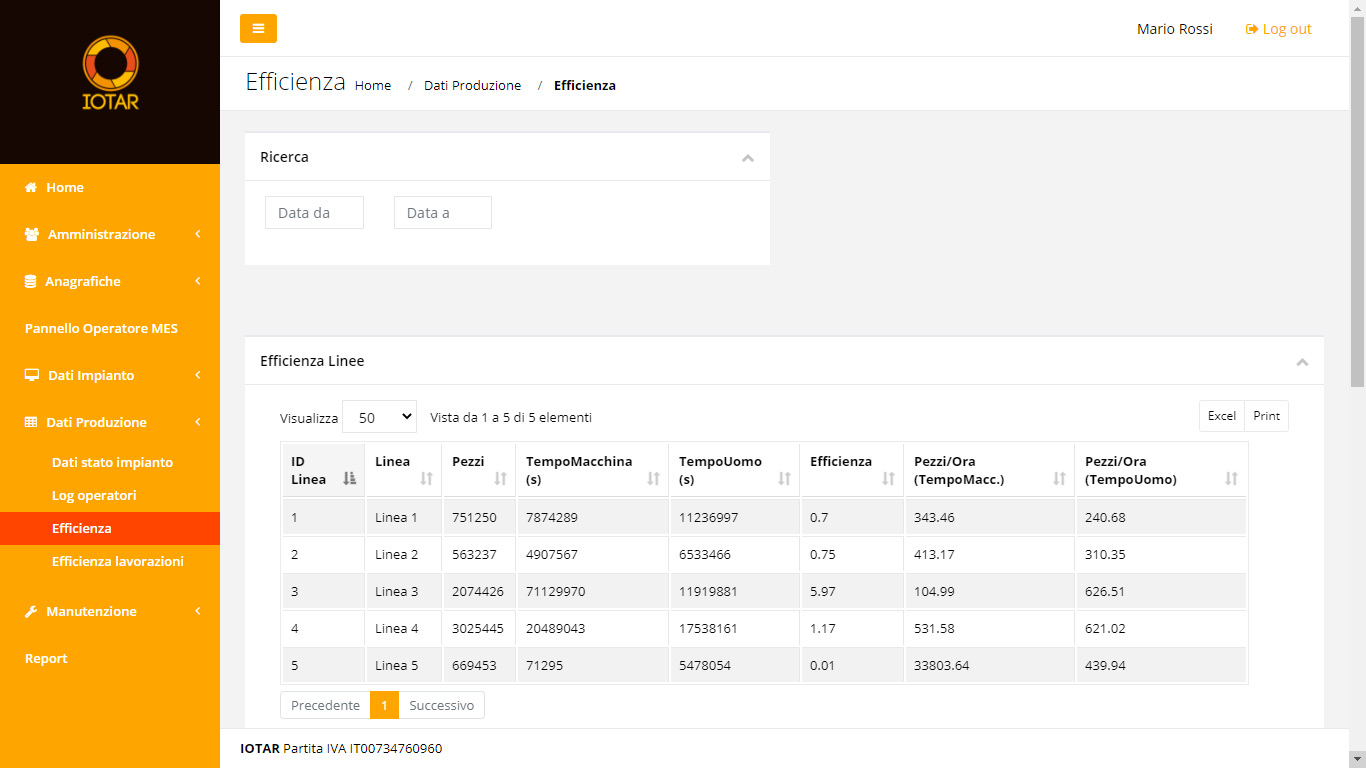

Data analysis is a series of operations that allow you to highlight useful information in achieving the intended purpose. These operations can involve real-time visualization of data, while providing a statistic of production, maintenance and employee activities.

One of the distinctive features of IOTAR MES is the wide range of management functions, such as the ability to import and export data that can be related to customer information, item management and item organization, in order to make smoother handling.

Finally, with IOTAR MES it is possible to schedule ordinary maintenance interventions and predictive maintenance interventions to avoid machine breakdowns that generate economic damage to the company.

Flexible, scalable and customizable for all needs

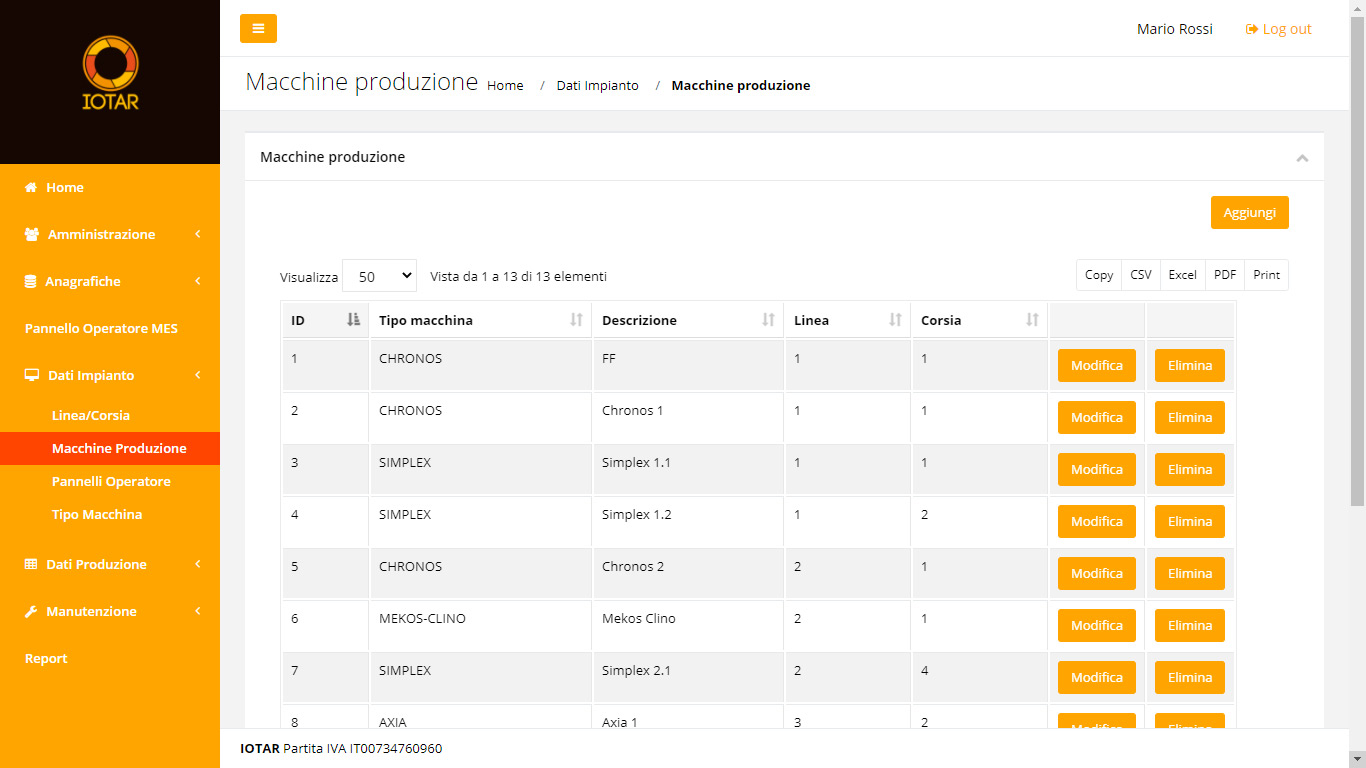

Integration with machines

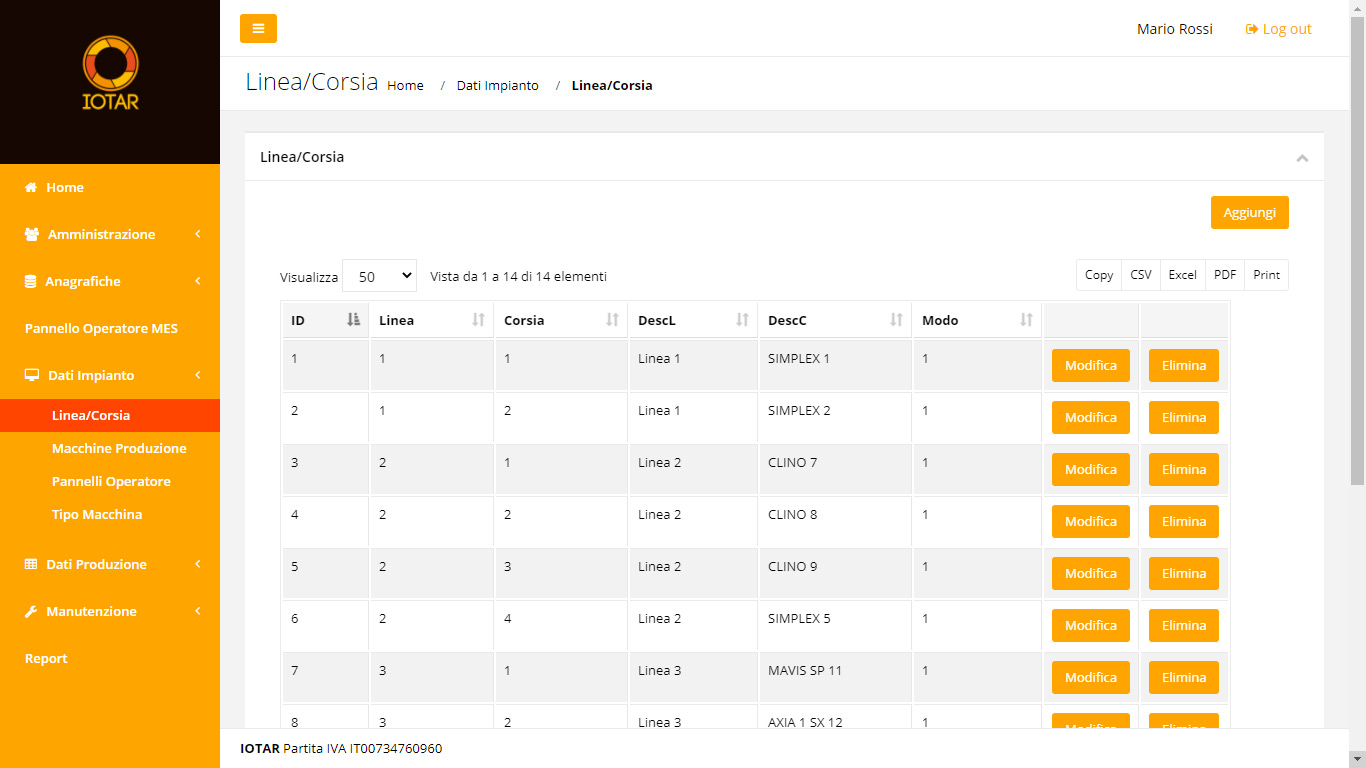

With IOTAR MES it is possible to connect to production plants by acquiring data directly from the machines and at the same time send data to the machines to automate activities, such as for example the configuration of the production line setups, effectively creating the interconnection required by Industry 4.0.

Monitoring and Proactivity

IOTAR MES is able to signal proactively and in real time the anomalies that occur in production (times too long, faults on the machines, etc.), it is therefore possible to act immediately on the problems and avoid damaging machine stops.

Production Programming

Programming production becomes extremely simple and fast with the IOTAR MES sequencer module which allows the department head to determine, starting from the order, the best sequences of operations on the various machines.

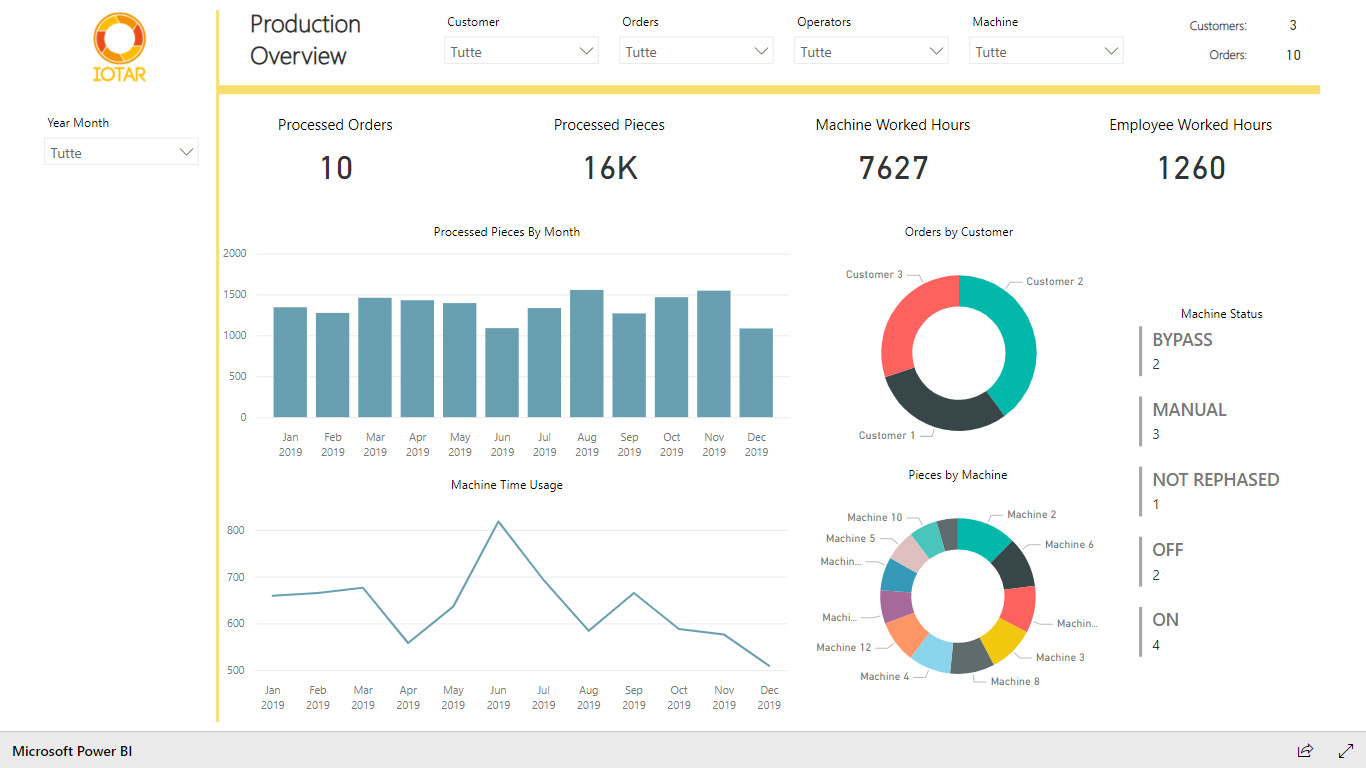

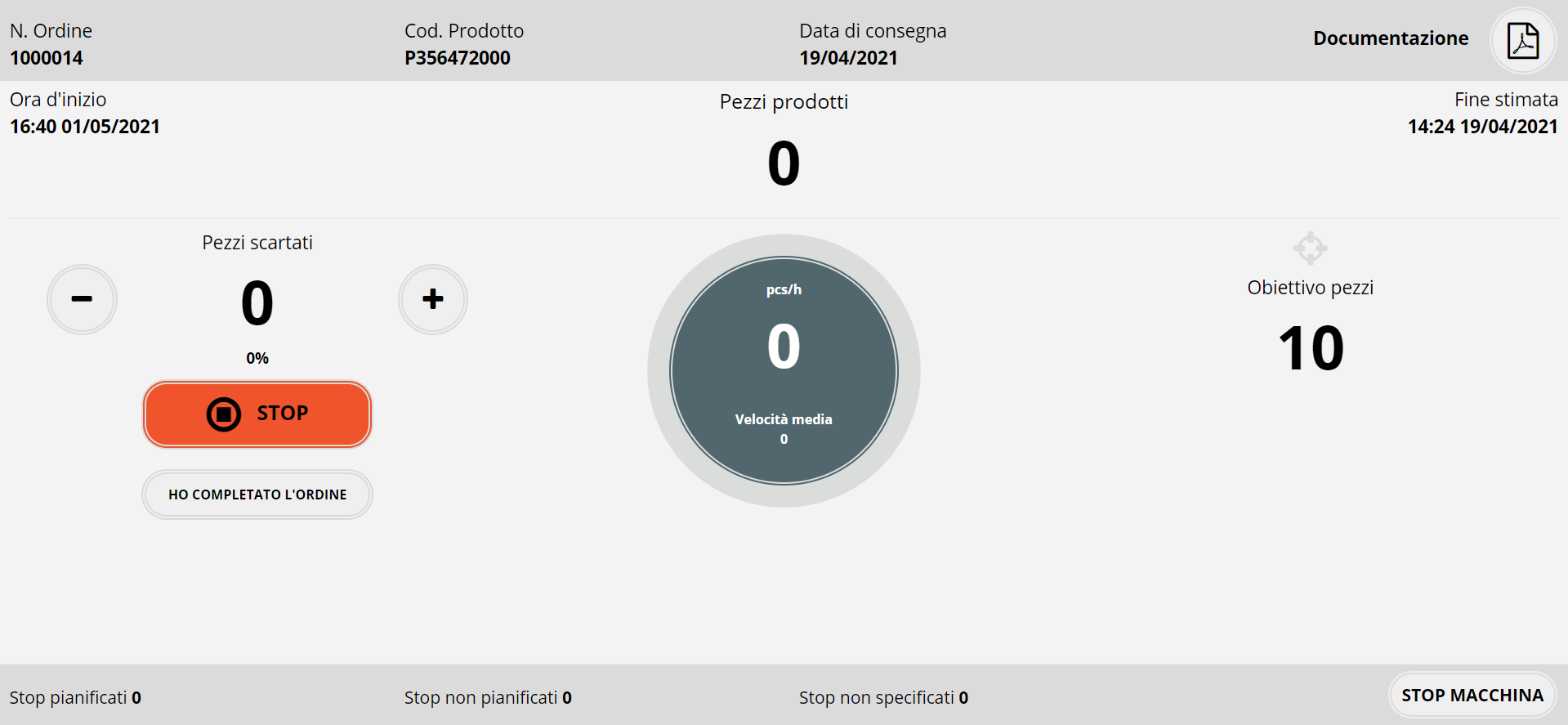

Dashboard

The IOTAR MES Dashboard allows you to monitor production performance in real time via the web (pc, tablet, smartphone) through preconfigured and customizable interactive graphs. The data shown in real time allows you to make decisions and act immediately in case of unexpected events with respect to the expected results.

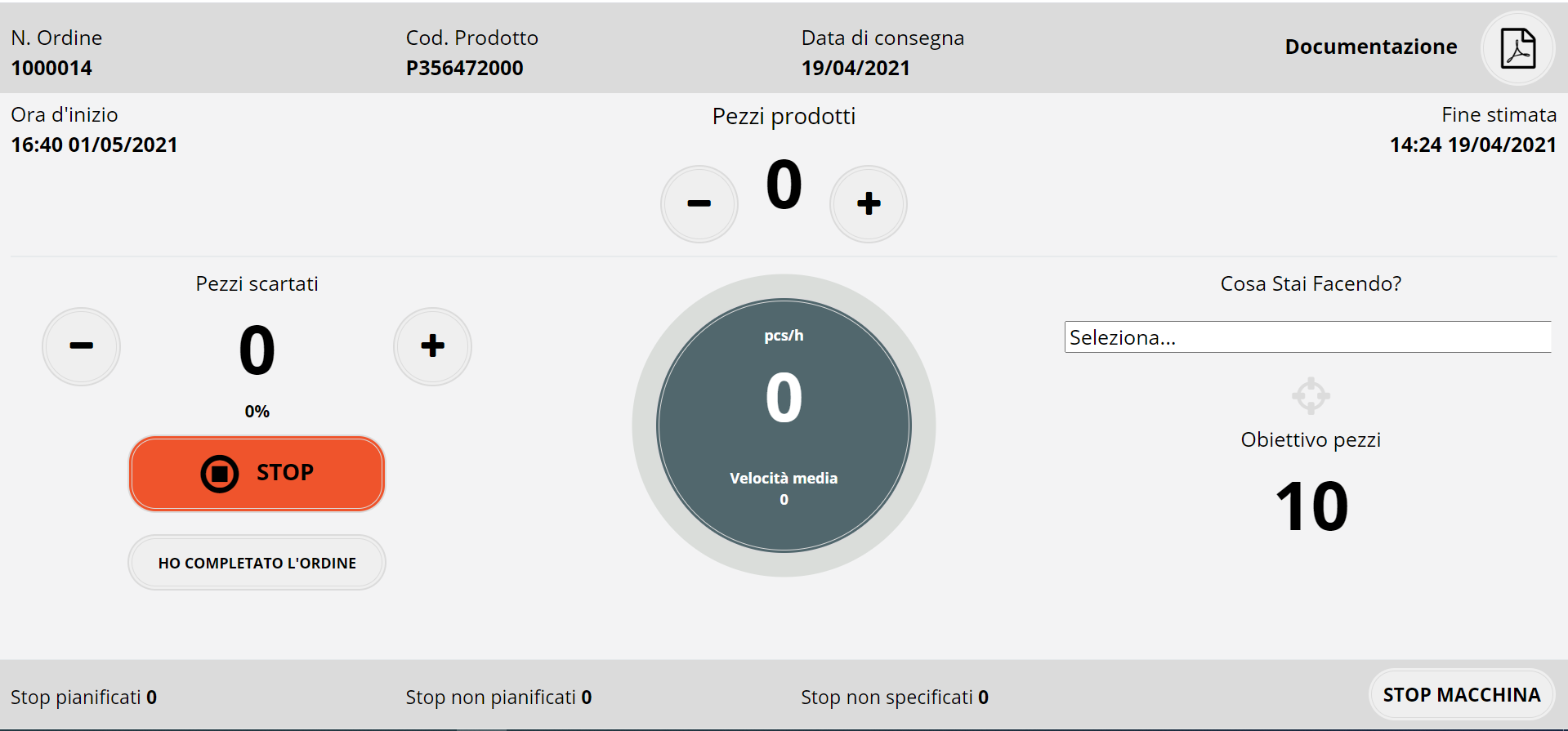

Data collection and progress

IOTAR MES collects data completely and correctly without the need for paper supports. Production progress declarations are made from PCs, tablets and smartphones via a web browser, making the activity data usable in real time, anytime, anywhere.

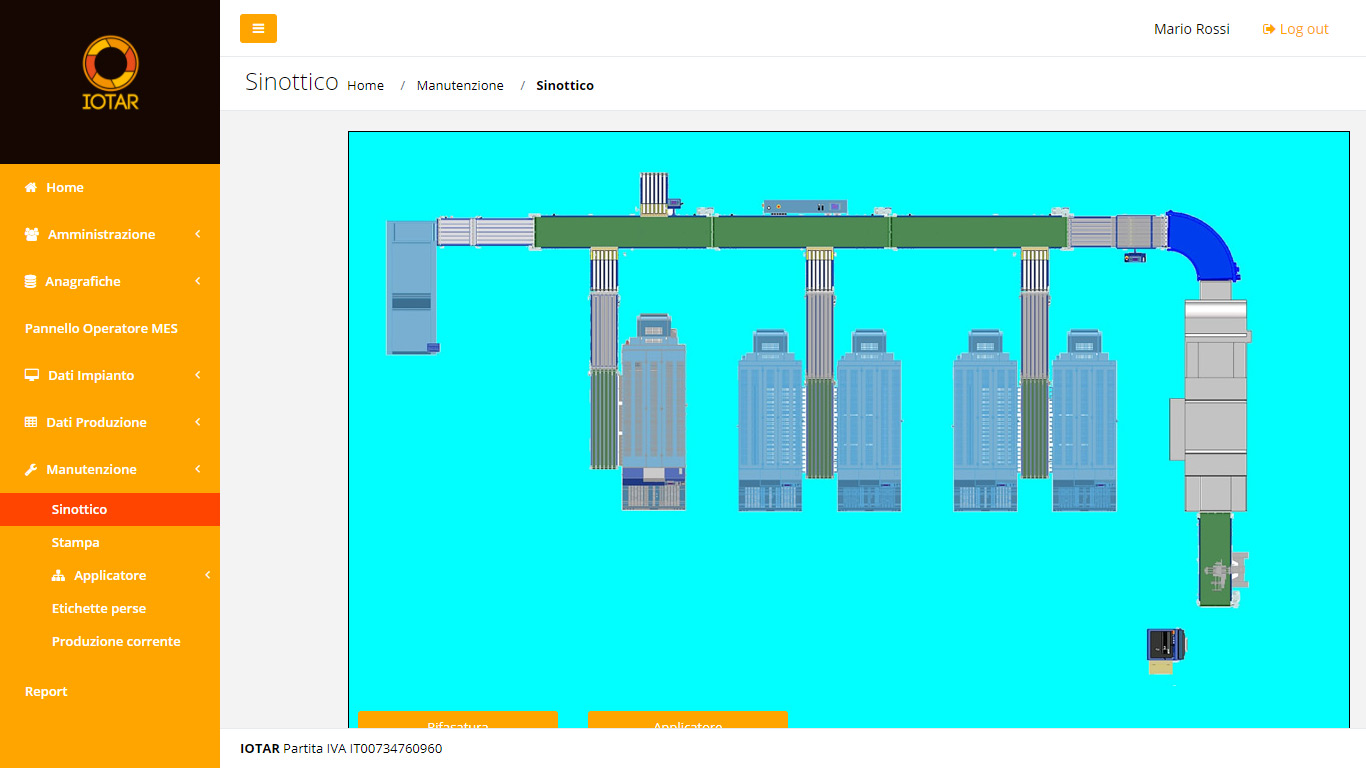

TPM maintenance

The TPM (Total Productive Maintenance) module present in IOTAR MES allows you to manage preventive, scheduled and fault-based maintenance in a computerized manner and integrated with the progress of production.

Traceability and tracking

IOTAR MES has complete handling management, both for individual materials and handling units (pallets, boxes, baskets, etc.). All movements are also perfected by lot and location, guaranteeing precise tracking and allowing optimization of logistics operations.

TQM quality controls

IOTAR MES is able to manage the process quality controls in a precise and reliable way both by the machine operators and by the quality control laboratories.

Warehouse Management (WMS)

The WMS (Warehouse Management System) is an IOTAR MES module that allows you to optimize all material handling (receipt, storage, picking for production, shipment, etc.) and to define or indicate their precise location.

Predictive maintenance

Companies that aspire to remain or reach the highest levels in their reference sector cannot avoid preparing a general efficiency plan, which touches every step of the production process, including concepts such as organization, logistics and plant maintenance and of machinery.

Precisely on the maintenance level, the company normally focuses only on the preventive maintenance, or a series of interventions to be carried out to improve the health conditions of plants and machinery with regular deadlines based on pre-established deadlines.

However, preventive maintenance does not allow the company to see fully effective maintenance guaranteed, as it is not based on an in-depth analysis of the state of things; in the long run this can become a problem because unforeseen faults can arise which fall within the reactive maintenance, which involves machine downtime with consequent economic loss and production delays.

Having said that, the preventive maintenance however, it is a step forward compared to the reactive one, with the analysis and collection of data and the working conditions of the machines and systems it is possible to prevent unexpected breakdowns. With the IOTAR MES management software it is possible to keep track of repairs and manage all maintenance-level procedures, collect machine data, environmental and production data, and therefore ideal for managing both preventive and predictive maintenance .

Our references

Contacts

Contact us for information or a free demo

INDEVO s.r.l.

Via Goffredo Mameli, 14

21013 Gallarate (VA)

Tel. +39 340 6356406