Vision Inspection System

Inspection of products with industrial vision

IOTAR is an industrial vision platform with optical scanner, designed with the aim of helping small or large businesses to solve production and warehouse management problems.

Think of owning a set of similar items to be identified by range or have to supervise conformity of production, highlight defects and manage the stock as fast and performing as possible.

IOTAR is able to learn quickly and automatically thanks to artificial intelligence modules.

Characteristics:

1. Assembly control and identification of deformed parts

2.Reading of letters

3.Verification of defects

4.Grouping texture and material

5.Identification of components

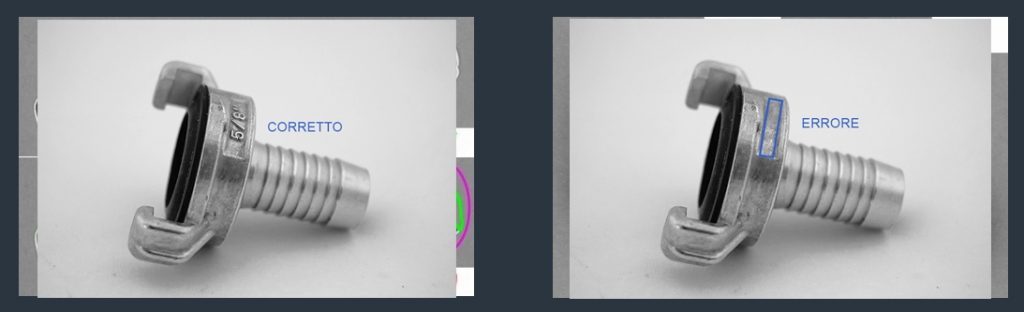

6.Conformity test, objectification

7.Optimisation of the warehouse

8.Analysis of similar or interchangeable products

The scanner can be installed in an autonomous station or integrated into automatic lines.

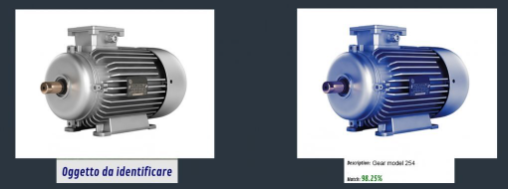

Identify the product

Identifies a product of any type or size within a set of similar items to be identified by range.

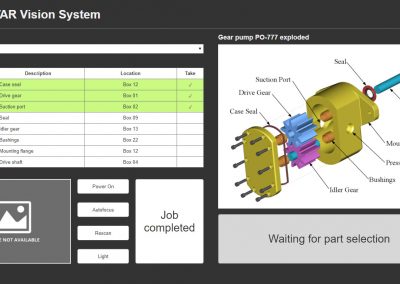

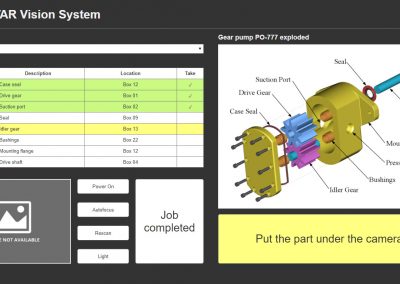

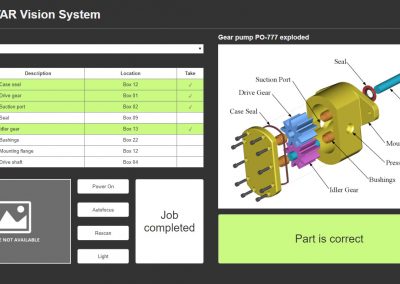

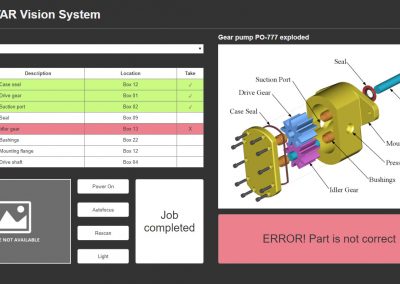

Manual assembly control

IOTAR is used to monitor production progress at each manual assembly location and to suggest to the operator the next steps or errors in real time.

Online control

IOTAR when integrated in line can automatically detect production defects (e.g. crease and/or dirty or broken fabrics, double weft, missing wire, overflowing, dimensional controls) and manage waste logic or production downtime in the most severe cases.

Quality control of the finished product

IOTAR monitors product quality for you, detects production non-conformities in order to highlight defects and manage the stock as fast and performing as possible.

Our references

Contacts

Contact us for information or a quote

Zinformatica

Via Goffredo Mameli, 14

21013 Gallarate (VA)

Tel. +39 340 6356406