ZWMS

ZWMS manages all warehouse logistics processes and tracks items at every stage

ZWMS is a system to effectively manage all warehouse logistics processes and provides functions to support the operational processes implemented by all companies:

- Management of incoming goods: During the reception, the correct presence of the items is checked in accordance with the order that can be imported into the system via convenient API.

- Allocation of goods: it concerns the processes of location, that manage the orders of positioning of the goods in the warehouse, establishing which is the best position for the articles in function of type, characteristics, dimensions. The rules and strategies are previously planned with the client and the mission management module is customized.

- Control and management of the stock: with this function it is possible to know in real time the situation of the supplyes and the supplyes, are prevented therefore eventual breakdowns of stock and is contributed to a better administrative management of the goodses.

- Outgoing Goods Management: Shipment processes are coordinated that concern the processing of orders sent to customers and transfers to other warehouses or returns to suppliers.

ZWMS is able to interface with the company management system, which deals with administrative management and therefore the activities that concern the warehouse from the accounting, tax and commercial point of view; it is also able to interface with the software used by any automated storage and handling systems present in the warehouse.

Our solution

ZWMS is a system that works in the cloud and exposes Apis with which you can integrate to manage all warehouse logistics processes.

ZWMS uses RFID tags to monitor incoming goods, movements and storage in the warehouse and allows you to verify outgoing goods.

As for incoming goods are read RFID codes through a portable reader or through a gate, the product codes are verified with the order of incoming goods produced by the customer’s management. The system is therefore able to verify the presence of all articles and possibly report errors of absence of products or incorrect codes.

After the control of the incoming goods, ZWMS assigns missions to the forklift operators to move the goods in the various storage sectors. The algorithm that manages the storage logic can be customized according to the needs of the customer. By means of intelligent forklifts it is possible to verify the paths taken by the various forklifts to reach the storage destination thanks to RFID tags placed on the floor that are read by the forklifts themselves. With smart forklifts you can also have a real-time verification of the exact location of the goods up to cell level.

ZWMS therefore allows you to know in real time the situation of the goods in stock thus preventing any stock breakage.

The exit of the goods is managed in the same way: from the managerial of the customer arrives the list of the articles to be shipped and at the same time a mission is created for the forklifts indicating to the operators the storage area from which to pick up the articles. The ZWMS system is able to verify if the operators on the forklift pick up the correct goods in the storage area and by means of RFID readers placed near the exit gates verify further the correctness of the moved goods.

For the technological infrastructure of the warehouse, we have developed a solution that avoids electrifying the entire warehouse and laying data cables throughout the structure. Our solution involves the use of passive tags embedded in the floor (to determine the position and paths of the forklifts) and other passive tags positioned in the storage areas and near the cells. The system is completed by equipping the forklifts with sensors (RFID, presence and distance) capable of determining the movements of the forklift, the load moved and the exact position in which it is stored up to the cell level. This system allows you to reduce 90% of the costs of the warehouse infrastructure compared to a traditional system, while ensuring a high precision and efficiency of the whole solution.

The ZWMS solution is customizable for any customer need.

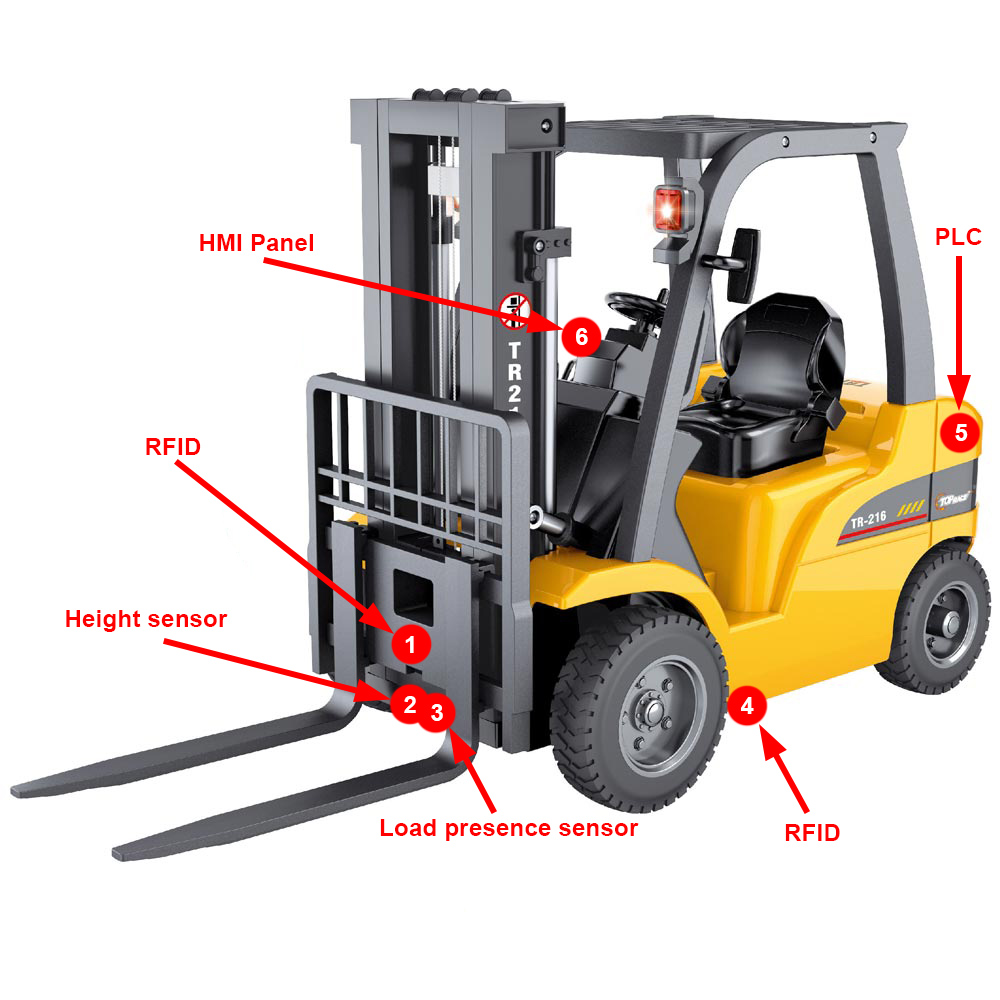

Intelligent forklift with RFID sensors

ZWMS can be interconnected with the ZWMS DEVICE device which can be installed on common forklifts to automatically identify the load, the movements of the forklift and the storage position of the load up to the cell level.

As you can see in the figure opposite, with the two ZWMS DEVICE modules it is possible to transform a common forklift into an intelligent forklift.

ZWMS DEVICE CORE MODULE

it is the heart of the whole intelligent system of the forklift, it receives data from the various sensors, processes the information and connects via Wi-Fi to the server for data exchange.

ZWMS DEVICE SENSOR MODULE

inside it contains a front RFID antenna – allows you to read the RFID TAGs positioned on the load; a fork height sensor – measures the height of the forklift’s forks to determine at what height the load was taken or deposited; a load presence sensor – this sensor checks the presence of the load on the forks of the forklift and finally a lower RFID antenna – reads the RFID tags positioned on the floor to understand the position of the forklift and the path taken

An HMI Panel can also be mounted on the forklift to show the forklift operator the missions and any error signals (load, column, cell, etc.).

Advantages with the introduction of WMS

- clearly advantageous prices compared to the standard solutions on the market

- optimisation of freight handling times

- the reduction of the times of evasion of the orders

- the rationalization of the spaces, thanks to the possibility to store any article in any location without danger of forgetting where the goods have been stored;

- the reduction of the recourse to the historical memory of the operators, in fact at every moment it is known exactly in which place or zone of the warehouse the goods are found;

- the reduction of supports

- increasing the productivity of operators;

- the possibility to consult real-time stock data;

- the possibility of having up-to-date statistics on the functioning of the warehouse;

- the reduction of errors due to manual management, thanks to the confirmation of the operation, and therefore a reduction of the related hidden costs

Our references

Contacts

Contact us for information or quotation

Zinformatica

Via Goffredo Mameli, 14

21013 Gallarate (VA)

Tel. +39 340 6356406