IOTAR ACQUISITION SW

Real-Time Data Acquisition Systems

A data acquisition system is a system designed to record and possibly post-process the measurements of one or more physical quantities.

Speaking of systems, we mean a set of instruments that, when properly connected and set, realize one or more measurement chains. Essential for these systems is that the measurements are recorded on supports (usually sql / no-sql databases) sufficiently stable to have the time to analyze them, or at the very least, be kept for documentary purposes for an indefinite time.

Towards industry 4.0 choose reliable partners

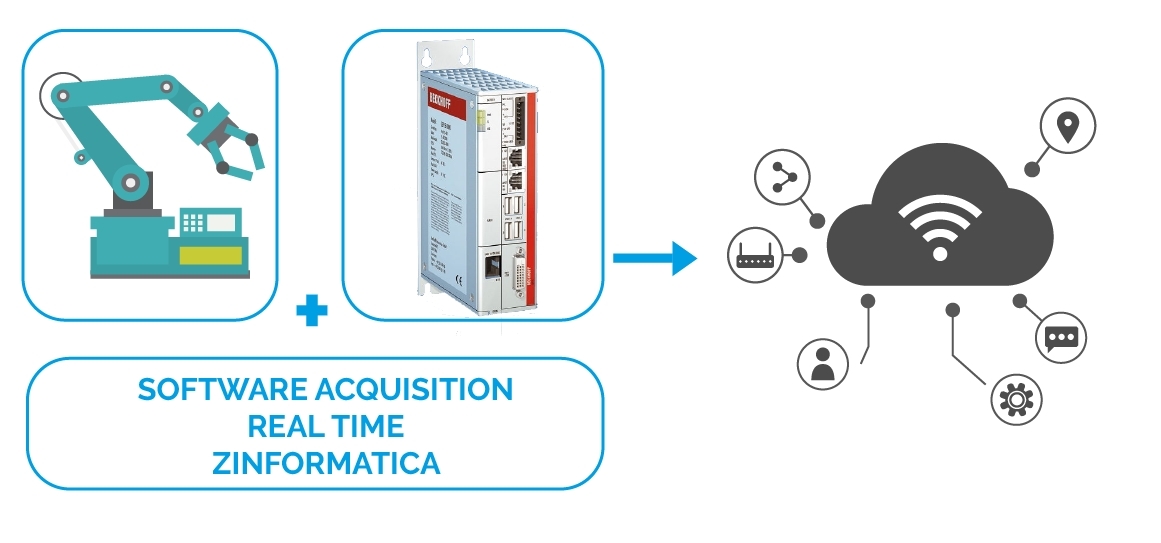

Our product IOTAR Acquisition SW is a black box consisting of a scheduled application with a web configurator aimed at acquiring and collecting data from the PLCs in a centralized database, public or private cloud, from the customer’s machines / database / files.

IOTAR ACQUISITION SW is a Real-time Data Acquisition System from PLCs for data acquisition (for example pieces produced, machine status, downtime, temperature, speed, A / D signals, pressures, torque values, high signals speed, etc.) from production machines; customized systems suitable for existing industrial infrastructures; this system is also equipped with a dedicated module to store up to 10 gb of data locally in the absence of network connection in case of transfer to a public cloud.

All data is collected by the PLC with the IOTAR Acquisition SW system in real time in SQL or NO-SQL database both in private and public Clouds.

Through a functional module our solutions allow to move and synchronize enormous amounts of data in a bidirectional way (thanks to an already tested module it is possible to move, by simple drag & drop, the data from the PLC to the Database).

The technical characteristics

• – easy to install pre-configured appliances

• – easy web setup

• – acquires data from all the most common industrial protocols with the highest performance.

• – offline temporary storage in case of lack of network connection

• – filter on acquired data

• – data storage on any type of database in private or public cloud

Our features

By integrating IOTAR Acquisition SW with the IOTAR MES module or with the IOTAR Viewer module it is possible to easily execute:

- Monitoring machines and consumption resources;

- The summary of labor times (through industrial terminals, barcodes, RFID, NFC, badges);

- Production line supervision, with time and machine stop detection (also with the innovative IOTAR Web App);

- More effective planning, scheduling and production scheduling;

- The management of planning and production orders thanks to the integration with ERP (Enterprise Resource Planning);

- The calculation of production efficiency;

- Careful quality control;

- End of line labeling;

- Maintenance management and planning;

- A more accurate warehouse and logistics management with goods tracking.

- We are able to acquire data from all the most common protocols in the industrial world with very high performance.

On request, for particular integrations with machines (PLC – Digital Signals – Piece Counters – Alarms) we create highly customized software (we prefer Beckhoff technologies, but we are able to adapt to the customer’s structure) using VB, C ++, C # technologies .NET and on IOT.

Our references

Contacts

Contact us for information or a quote

Zinformatica

Via Goffredo Mameli, 14

21013 Gallarate (VA)

Tel. +39 340 6356406